Please browse the featured MK products or search for a specific model

Please contact us for more detailed product information, availability and pricing.

Thank you

for your business with

Precision Zone!

Precision Zone has been selected by MK Technology Group as their authorized distributor in the USA.

MK Technology was founded in 1966 in Germany and quickly grew to become a prominent player in the framing solutions industry in Europe. Now with a US based representative office MK is expanding its foothold in the USA as well. We at Precision Zone are proud to be part of this expansion and are investing our resources and competent team to supporting our customers by providing detailed information about MK products, stocking and selling MK products, focusing primarily on the profile systems and related components."

Precision Zone stocks, sells and supports a wide range of MK Technology framing products.

There are a few factors that set us apart from competition:

Please feel free to browse our web site or contact us directly with inquiries or questions.

Thank you for your interest in Precision Zone!

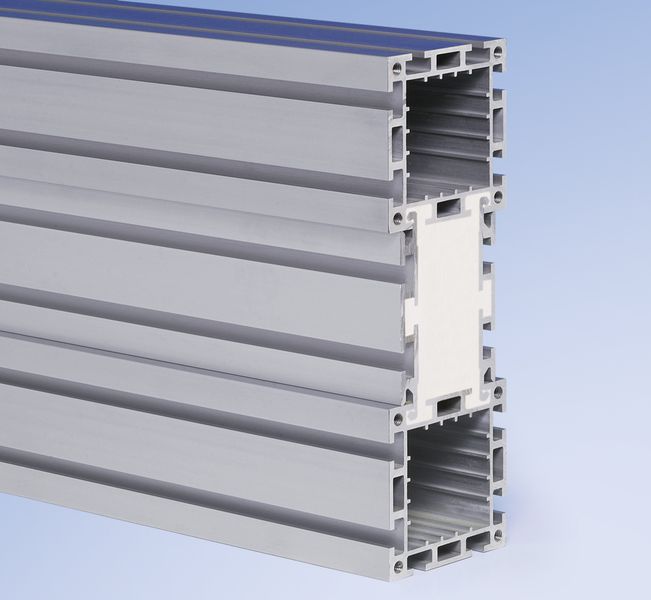

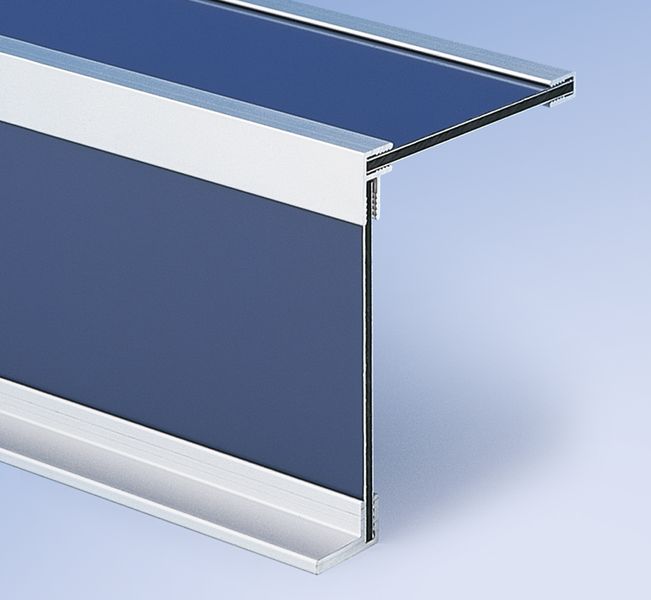

MK Technology Group has developed a comprehensive range of profile systems and related components that are widely used in many industrial applications such as guarding, materials handling, automation, manufacturing, robotics, linear motion to name a few. Boasting german engineering excellence and uncompromised quality, MK profiles are a perfect fit for any framing project you might be working on.

Advantages of the MK Profile Technology

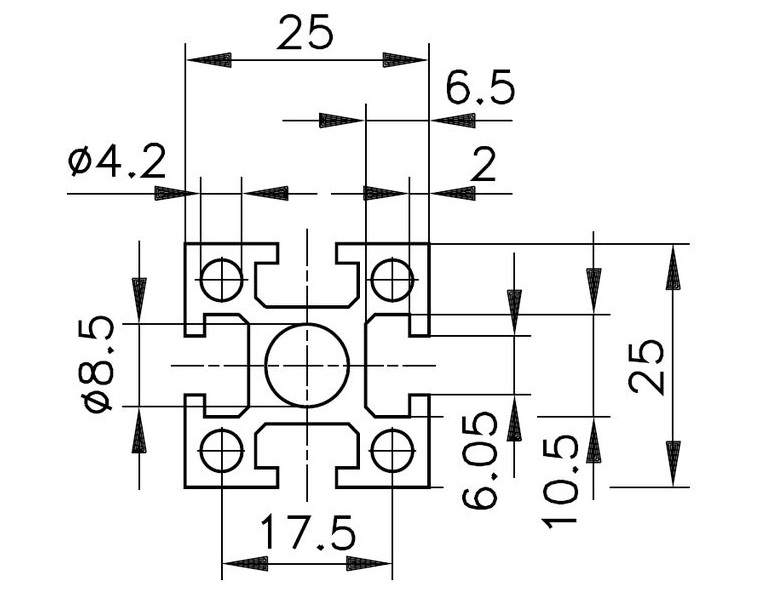

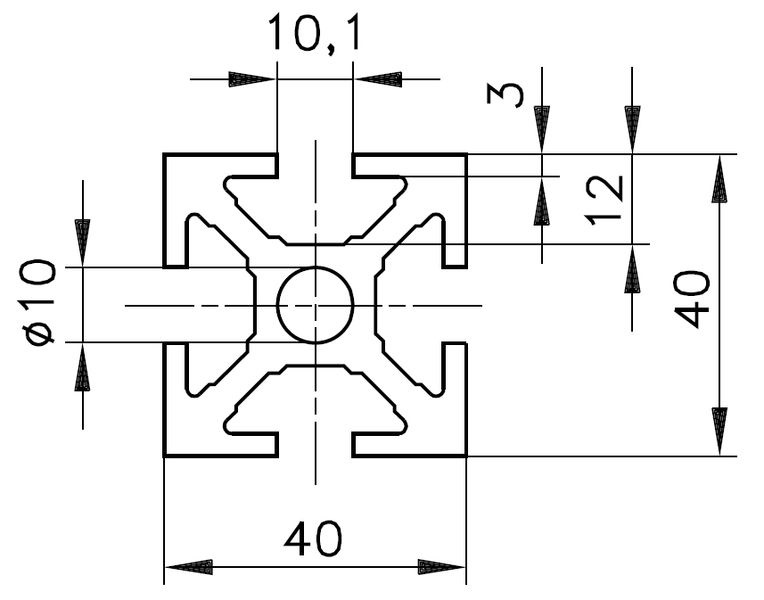

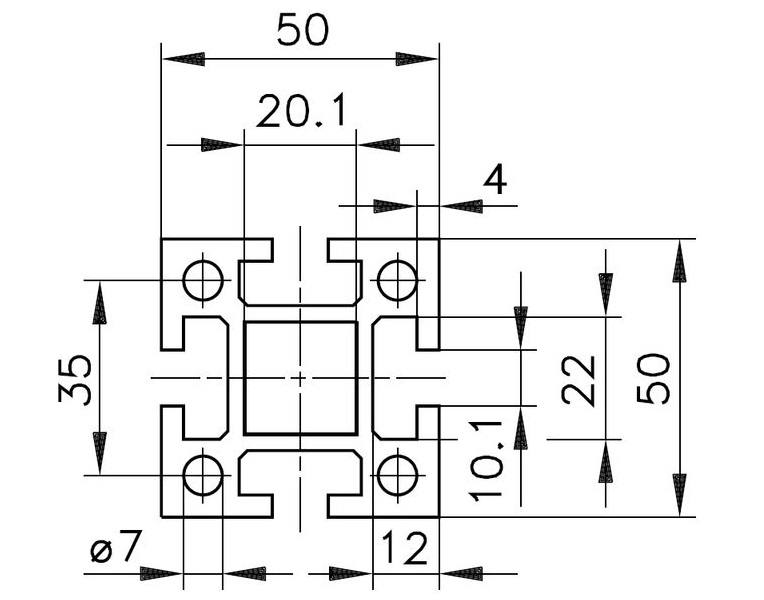

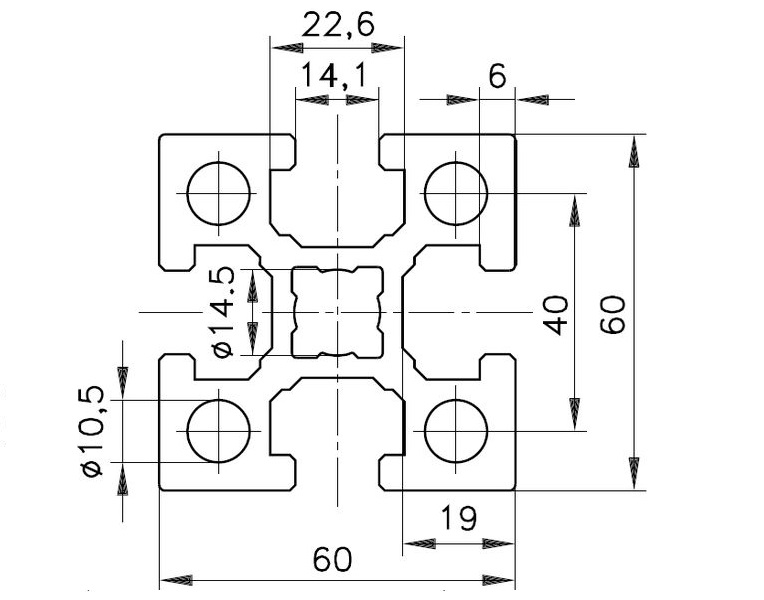

Profile Series

Typical applications:

lightweight frames, display cabinets, measuring and test equipment, electronics housings

Typical applications:

machine frames, guarding, equipment construction, assembly workstations, guardrails, treads and platforms

Typical applications:

heavy frames, racks, and bearing constructions

Typical applications:

machine frames with high loads and for large portals

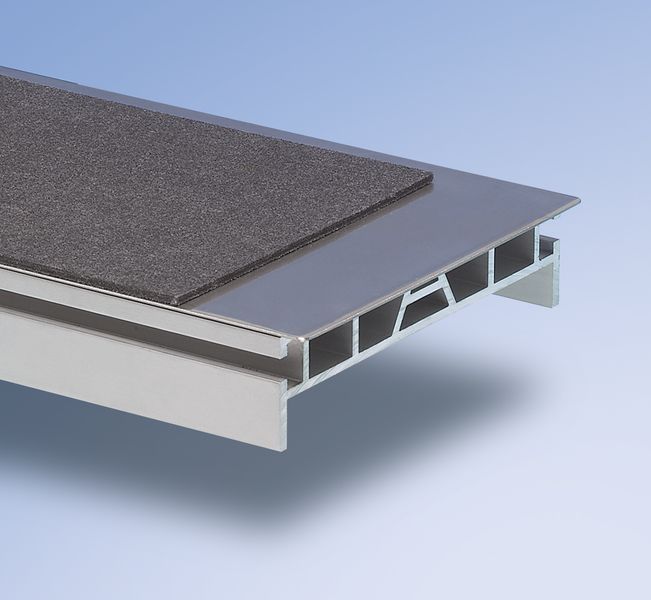

Application Profiles

Our application profiles include:

By combining series 40, 50 or 60 profiles with our connection profiles, a cavity is produced, which through filling with foam, connects the cross sections together so that they are inseparable. With this combination we produce individual cross sections up to 420 x 240 mm and spans of up to 12 m. In addition to the connection task the foam also has a vibration-absorbing characteristic. Foamed profiles are used for long, solid linear axes or for girders, columns and portals.

MK's connection technology is versatile and gives you complete freedom in the design of your construction. Any angle desired can be realized. All assembly components use standard screws. You can choose from angle connections, console connections, tension connections, connecting plates, corner connections, truss joints or clamps. With this selection we always offer you the optimal connection technology depending on the requirements.

Accessory Components

Accessory components from MK fit perfectly into the mk modular system. Thus profile constructions can be custom configured to meet your requirements. The extensive assortment includes:

Building on the base technology of the profile systems, MK developed an economical and comprehensive product line of modules, components and single parts for your individual tooling shop.

Advantages of the MK Factory Equipment: